When he was younger he wanted to become a vet, but today Joost Donkers feels right at home as Director Supply Chain Business Group Ingredients at FrieslandCampina – the role in which he was also voted Supply Chain Professional 2018. His motto: try to simplify things. “In that context, we’ve thought up ‘four times zero’: zero accidents, zero quality issues, zero missed orders and zero losses. It’s a nice slogan that’s easy for employees to remember.”

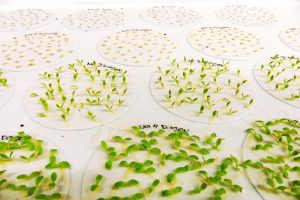

FrieslandCampina processes milk into milk proteins, whey proteins, fats and lactose. The Business Group Ingredients sells these products to the pharmaceutical industry and food manufacturers who use them to make things like specialized nutritional products and supplements for humans and animals. The raw materials are used to produce baby formula, including under the company’s own label: Friso. They are also found in consumer products such as coffee creamers, bakery products and dairy drinks. The sales offices, research departments and manufacturing facilities (in the Netherlands, Germany, the USA, Brazil, Egypt, New Zealand and Asia) are grouped together in clusters: single ingredients, baby food, encapsulated ingredients and a joint venture with DFE Pharma. The four manufacturing directors report directly to Joost Donkers. Besides them, his team comprises the director of sales and operations planning, distribution and outsourcing, and the performance excellence director. Donkers: “We’ve also grouped together other people who have similar knowledge and expertise, such as HR, finance, purchasing and quality assurance. They report to their own section head, but they also have a reporting line to me. That greatly improves information sharing. I’m not someone who manages at detail level, and I believe strongly in a model based on indirect reports.”

Each of the companies in your business group used to have its own supply chain. Why has that changed?

“We discovered that we weren’t the best-in-class. We closed that 10-to-15-year gap in the space of four years by bringing together people with the right passion and a shared goal. My award was recognition of that, so we’ve shared it among all the 120 man – agers in my supply chain. It was a challenge, because although our factories are spread around the world they are closely linked by the product flows. If something goes wrong in one factory, it affects a lot of others too. Our network is also pretty full, so we don’t have much room to divert production. Plus we’re in a growth market with annual investment of more than €150 million. It was a huge help that the then-boss was a strong advocate of business-group-oriented supply chains. The manufacturing directors initially found it hard to adapt to the new way of working, but they’ve now got used to managing a functional rather than hierarchical organization.”

How will you make the next leap?

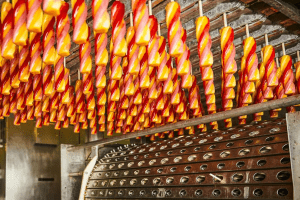

“We’re on the cusp of making choices about groundbreaking technologies in an industry which has done things the same way for the past 60 to 100 years. Some of our powder machines are half a century old and still gas-powered, so it makes sense to invest now. Drying milk and whey is an energy-intensive and labour-intensive process. Our people have some impressive ideas about energy recovery and the use of electricity and geothermal energy instead of gas, which we’re developing with external partners. Our Borculo factory has switched to using biogas from the local waste treatment plant and pyrolysis oil. And we’re currently talking to a customer about supplying a product in liquid form in order to miss out the drying process completely. Alginate is recovered from our waste water for reuse. To be honest, I wish I could have made these investments earlier and in smaller doses, because there’s now a lot going on all at once. Our network is so full that we have to tackle one factory at a time, because they are out of the running for weeks and sometimes months. We provide all major pharmaceutical companies with medical nutrition for hospitals and products for premature babies. Lives are at risk, so failure to supply is not an option.”

Are you also using this investment period as an opportunity to improve your processes?

“In process technology, they work with centralized control rooms; an operator has to check whether everything is OK every three minutes. But wouldn’t it be great if that could be reduced to once every three hours? Our factories are working round the clock. The operators are crucial because they have to make the right decisions. We’re training them in factory management principles – such as to make results visible and to ask questions to prevent problems from reoccurring – with as little classroom-based learning as possible. I believe in on-the- job training, and the HR managers and line managers join the sessions. It’s very rewarding to see the operators’ pride in what they have achieved. We’ve also given them the lead in improve – ment projects, such as scheduling the sampling in tanks for various departments. The operators evaluate the situation them – selves and then think up the most logical route. The maintenance used to be done by a separate department, but the initial responsibility now lies with the operators because they know the machines. When they’ve completed their course in autonomous maintenance you see them walking around the factory with a big grin on their faces, carrying their toolbox and making sure everything works again. Plus the maintenance department can now focus on strategic improvements.”

You’ve been working on tracking and tracing over the past year. Why?

“That’s important in pharma and baby food. In the wake of all the scandals, customers in China and Hong Kong want to be sure about the quality of baby food. At FrieslandCampina we have the whole chain under control, from farm to fork. A shopper can scan the QR code on the packaging and see all the sup – ply chain information. We also use the codes ourselves for track and trace purposes. In the case of an incident, we can withdraw specific batches from sale and provide certainty for retailers and governments alike. The pharmaceutical world demands that certainty too. If it works in China and Hong Kong – our biggest baby food market in Asia – we’ll implement it worldwide.”

If you could start from scratch, how would you design the processes?

“Our production facilities have often grown from village dairy companies. They have close ties with their local community, and that’s a good fit with us as a cooperative, but they are often hemmed in by urbanization and are a source of nuisance in terms of traffic and noise. So it’s my dream to have a Dairy Park where we bring the supply chain together. Instead of spending money on maintenance, we should perhaps dare to build some – thing new in a central location with good HGV access where we can produce milk, cheese products, whey for baby food and so on. We could invite suppliers such as packaging manufacturers to have a base there too. I’ve suggested this idea internally and most of the feedback was positive. There are no concrete plans so far, but I’ve opened the door far enough that we now consider not only existing locations but also new ones when discussing investment plans – not because I want to, but because it’s more practical. And the idea isn’t to close existing factories, but to build additional ones.”