Nivea is one of the world’s best-known skin care products. But its manufacturer Beiersdorf is ‘relatively small’, according to Harald Emberger. Having worked for Mars Inc and Unilever he might say that. Emberger joined Hamburg-based Beiersdorf in 2015 with a brief to setup an end-to-end supply chain. “That had been my dream. Supply chain is my passion and I am fully dedicated to it. It’s about creating value and always having an impact in whatever you do.” Beiersdorf is actually one of the world’s largest producers of skin care products and adhesives with a sales revenue of around €7 billion in 2020. As well as Nivea, its brands include Eucerin, Hansaplast, La Prairie and Labello. Today the company is injecting innovative solutions into its supply chain to catch up and surpass its competitors. Emberger combines this ambition with a realistic approach to create agility and speed in today’s uncertain world.

In 2017 Beiersdorf was hit by a cyber-attack which momentarily shut down its operations. It was a wakeup call for the German multinational, whose international business dates back to the end of the 1880s. The company put new focus on agility, innovation technology, efficiencies and people. Its current roadmap includes expansion of factories, digitalization, innovation technology and sustainability as it moves towards a realtime supply chain.

While sales dipped last year during the pandemic the company accelerated the implementation of these strategic priorities and says it will invest an additional €300 million over the next five years. Its new technology centre has a start-up approach and is a powerful tool for the fast integration of new innovations in the supply chain. Training and retaining talent are also a priority.

“The world is changing so fast that the skills we will need in 10-15 years will be at a different level,” says Harald Emberger, CSCO Beiersdorf, as he describes his current role.

What have been the turning points in your career that have led to your current position?

“I studied mechanical engineering in Munich but, which was quite unusual, I did not join the automotive industry; I found its environment too restrictive. Instead, I joined food company Mars Inc where there was much more opportunity to work on larger projects.

I led a factory in the UK which taught me the DNA of manufacturing. Then, in the early 1990s, I had the chance to build and lead an operation in the Baltic states. It was a difficult environment, a big investment for the company and I was working with a very young local team. We built a large, modern factory for over 7000 employees which was operating within weeks to nominal capacity. It proved to me that with the right talent you can achieve anything you want. It had a huge impact on my personal development.

Another turning point was when I was sent to close the Mars location in Germany. However, we didn’t close it: Instead, we radically transformed the factory. At that point I realised the impact you can have as supply chain leader. Instead of pampering the problem we reassessed the entire workforce of 650 people and sent the top 30 candidates off for training. We gave them more responsibility and suddenly team leaders were operators and vice-versa. It was a huge strategic shift with a phenomenal result.

I then moved to the US to run the North American supply chain for Mars, where I learned a lot about the American mindset: While loyalty, passion and will-power drive things forward, it is a very competitive environment. The US is also incredibly resilient and will probably come out of COVID pandemic very strong.

My next move was to Unilever where I was responsible for supply chain in North and South America. It was a USD 17 billion business with 70 factories, 30,000 employees and 4 categories (from ambient to frozen to chilled to home care). In North America the supply chain underwent a complete restructuring while in South America, which was growing so rapidly, we were investing with the growth.

However, the job at Unilever involved a lot of heavy travelling so when in 2015 I was offered this opportunity at Beiersdorf I took it. It had been my dream to run an end-to-end supply chain and here my brief was to do just that and make it a competitive part of the business.”

What are your responsibilities as chief supply chain officer?

“My responsibilities include direct and indirect procurement; planning; manufacturing including that of third parties; global logistics; IT and process engineering; customer service; logistics, quality management and our training academies. I have strong dotted lines to finance, HR and our business units in the markets. I am also responsible for a unique group we call technology innovation. This is a team of ten people with one project leader whose objective is to get innovations into factories fast and in a sustainable way. It has proved to be a very powerful tool. We have also integrated engineering into this group for end-to end design, such as of the nine factory investments we are currently working on. In total, we have 16 plants globally at the moment. I have 14 direct reports and around 7000-8000 indirect if we include all the factories.

The organization is divided into three regions – Europe, Americas and RuMEA. Each region has a supply chain head who has end-to-end responsibility, from the factories to market, and we have regional management boards.

It’s important to have this capability in the region which knows the priorities and when to make the calls. However, the overall integration of the value stream is run centrally: I cannot afford to have multiple interests and conflicts. I need a responsive agile supply chain and it doesn’t work if there is a conflict between manufacturing, that wants to drive efficiencies, and go-to-market that wants to drive customer service. Therefore, I set a very strict operating model for the factories, the so-called BMOS system (Business intelligence manufacturing operating system). In this way the factories are structured and their efficiency targets and agility are set and managed globally to ensure that we don’t lose sight of efficiency.”

So if you have a strict operating model why have three regions? Do the regions behave so differently?

“Yes, for example in Europe and China, the omni channels are very different, especially when you look at our b-to-c business or e-commerce. So we need a very different set-up and skill-set. In Europe we can centralise more but in China we need to get closer to the market to stay agile.”

How did COVID impact Beiersdorf as a company and in supply chain?

“We supply skin and face care products and both were negatively impacted in 2020. When people are mostly at home it’s not surprising that we were adversely affected. However, we did gain market share and our supply chain had the best year ever in 2020.

We have been relentlessly improving since 2017 when we were hit by a cyber-attack and the company was down for two weeks. We recovered well and it opened up a lot of opportunities to improve the way we run, plan and synchronize our factories. The improvement was based on four pillars: Agility, innovation technology, efficiency and people. We invested a lot in our people capabilities, especially in planners, through our academy and training. We realized that our most critical people are in fulfilment: if a planner makes a mistake it can cost a fortune.

Also, throughout the pandemic we have continued to invest in the network. We have expanded our factories in Brazil, Poland and Mexico, and we lowered the base load in factories to 75% which has made us more flexible and agile. It was a big call and we could only do it by combining it with our strong operation systems, BMOS and MANEX.”

Your new road map takes you through to 2025. What are its priorities and did you create it with the pandemic in mind?

“We had already started and so we built it in parallel to COVID. As well as the two classic pillars of continuous performance and process excellence we focus on four areas.

Firstly, network design: Our shift now is from factory expansion to logistics. In future the supply chain will become more real time and we will need enormous logistics capabilities. The factories in which we’ve already invested have huge capacity for late-stage differentiation for e-commerce and integrated value-added services. We can change products and packaging formats at a late stage and fast. Also, for direct-to-consumer sales we need to have huge flexibility in the warehouses with advanced picking capabilities.

We’ve consolidated global transport movements into control towers and although we don’t yet have real time visibility we are getting there. Fortunately, logistics providers are becoming more digitalized and understand the global approach better. For me, running an integrated business is a base requirement. We have 50,000 SKUs and probably change two thirds every year so we need enormous agility. Collaboration with suppliers and customers always comes first.

Our second area of focus is digitalization: We’ve integrated end-to-end planning within the organisation and we’re implementing business automation for processes such as order-to-cash and purchase-to-pay. Also, we have robotic process automation (RPA) in place, for example in procurement to provide quotes and for customer service. We use AI in procurement for predictive analysis of suppliers and within the factories for preventive maintenance and end-to-end connective planning. We digitalized about 80% of procurement last year and the AI tools helped us to predict supply shortages faster than the suppliers informed us. We managed ahead of time to build in resilience.

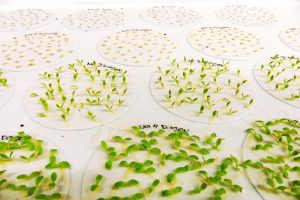

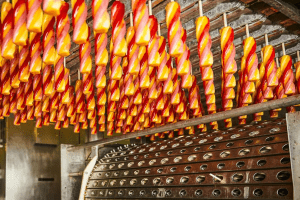

Thirdly is innovation technology. We’re investing over 60 million euros in our technology centre in order to innovate faster and leverage our high agility and speed. We also need to know if the product works or not before we scale-up, especially as product life cycles are short. Beiersdorf has strong, standardized process technology which we can build on further with advanced capabilities, for example through nano technology. We strongly believe that with this set up we give the company a competitive edge and we can respond faster than the competitors.”

So the technology centre is driving investment in the supply chain’s end-to-end capability?

“Two things, in the past we have not focused enough on the combination of product and packaging to build a competitive edge. In our technology centre we can run full production lines on a small scale which allows us to design products and packaging together as we can look into more complex and difficult filling technologies and more continuous processes.

Secondly, we set this up collaboratively with specialized suppliers of machines and chemicals because it does not make sense to do it all by ourselves: The trends in our industry are to use less preservatives, more active ingredients and have more sensitive formulations all of which require enormous specialized knowledge.

Lastly, and what drives me, is that the tech centre is a strong training ground for our talents because here they are exposed to end-to-end technology.”

How do you see the role of technological innovations, such as RPA or service innovation through social media, as part of a successful strategy?

“We see two mega trends in supply chain: Firstly, we see the acceleration of a real time supply chain which requires lots of capabilities and enormous agility. Secondly, the classic linear supply chain from supplier to customer is changing into a cubical one. More points feed into the chain and customers will be best served via a choice of options. In future we will be able to leverage more suppliers and work with more short-term third parties.

The whole company will work with one data base. The challenge is how to set-up the IT structure so that we have the capability to consolidate all data, including social media, into one system and then run algorithms/analytics through a single pool to provide product trends and supplier solutions.

We know that the younger generation want things as they see them: Some products sell out in 30 to 40 minutes. We are building a system which incorporates all social media data from consumers and translates this into orders and fulfilment.

We also work with sell-out data and soon we will integrate a global system that will give us better clarity of on-shelf availability. Demand sensing is on the same platform and we work a lot on data mining which has been very successful. Ideally, we will have a set of suppliers from which to choose in line with the speed of change. This is how the business is developing.”

What does it mean for employees, who are trained for traditional operations and now have to work with social media and consumer behaviour? Are they ready?

“It is difficult because for years planners have been using and trusting their own numbers to make a forecast. In future they will get prescriptive analytics, partially based on social media, and they will have to judge whether or not the figures make sense. On top of that they need to have the skills and capability to convince a board or leadership team that their business forecast makes sense.

Similarly, in future a technician will see via an on-screen algorithm where a machine is broken, or will break, and needs to be fixed. Will they trust it or not? Our biggest challenge is to build up and retain the right talent and capabilities within the business.

After the cyber-attack in 2017 we introduced academies for logistics, planning, procurement, sales and quality. We also invested in online programs to ensure that everyone is trained. Following that we actively build career paths by giving people additional responsibilities in country or regional roles so they see opportunity to grow. Thirdly we get involved in every career move globally and actively rotate positions, between factories and for example procurement or go-to-market, which is easier from a central leadership.

We want to make sure we keep the skills and build further. The supply chain is changing the most rapid in terms of the tools we have, the uncertainties and the requirement for sustainability. Three or four aspects are coming together simultaneously but they are still very ambiguous. The skills we will need in 10-15 years will be at a different level so I’d rather leverage as much as I can at the moment so that people can grow and learn, technically, operationally and leadership-wise.”

How did you design and deliver the fourth pillar – sustainability – of the road map?

“On one hand sustainability offers a super opportunity but on the other, it’s a massive challenge because it’s such a wide topic. Beiersdorf has a new sustainability agenda, Care Beyond Skin, which is an integral part of our C.A.R.E.+ corporate strategy. It defines seven focus fields, in the areas of environment, society and consumer. The corporate sustainability department controls and monitors the measures implemented and reports directly to the respective Executive Board Member.

We started with the factories and our target is to be climate neutral by 2030. All factories have solar panels and we are already zero waste-to-landfill. We have accelerated product formulations and pledged a 30% reduction in fossil-based virgin plastic by 2025, compared with 2019, by light-weighting and accelerating the use of recycled and renewable plastic. We also want to reduce water consumption per manufactured product by 25% by 2025, compared with 2018.

It has been a massive learning curve and everyone in the company has shown great passion and support as we catch up in this area. We have made huge strides. A lot is thanks to our technical innovation capability at central level which allows us to implement very quickly. I believe this is where we have competitive advantage.”

It is a challenge for a leader to design a roadmap but how do you ensure that you deliver it?

“Firstly, we built the roadmap with the team, not top down, and did the analytics together. Secondly, it’s important that a road map is simple to follow to ensure that it’s used.

We have constant tracking and we communicate globally every quarter. As needs change this is deployed through the team. However, for a centric organisation like ours, it’s easy to assume that things are taken up immediately. However, it can take three to four years before someone on the other side of the world takes it on board. The sign of success for me was when we saw the roadmap being used as part of local presentations.”

Looking to the future, what do you see as the main role for supply chain within the business?

“Supply chain will give the company a competitive edge and this will be driven by digitalisation and the requirements for sustainability. It will become an integral part of the management of the business, especially in the e-commerce environment which is totally dependent on innovation in the supply chain.”