“The right doors opened for me at the right time,” says Isabelle Conrot who has spent her entire career – 27 years – working for the Swiss healthcare company, Roche. Always curious to see where they led, she’s enjoyed a varied and buoyant career, the last 4 ½ years as Head of Global Logistics & Supply Chain Operations for the Pharma division. Her latest challenge was to lead and shape a lean and sustainable logistics and supply chain operations organisation while adapting to the current and future needs of patients and making an impact for Roche. That was only possible with a change in mindset in her whole organisation, a change that also helped them through the Covid pandemic. “I want my legacy to be a lean and agile supply chain organisation that adds value and where people can perform at their best,” she says.

A single mother of twin girls, now aged 23, she’s very proud of them and what she’s been able to achieve. “It’s not always been easy combining my career with personal life but I never considered myself a victim. You take ownership of the situation and you decide yourself what you do with your life.” At some stage in the future the pharmacist would like to spend more time with her new partner in Sri Lanka, where she has a house, and deepen her interest in the Ayurveda culture, including its natural remedies.

Roche is a world leader in biopharmaceuticals and cancer treatments and renowned for breaking boundaries in healthcare. Today, with more than 100,000 employees in over 100 countries, the 125- year old company continues to prevent, diagnose and treat diseases and make a sustainable contribution to society. The supply chain is having to balance efficiency and sustainability with the aim to be more patient centric. “I see the supply chain as the backbone of the business,” says Dr. Isabelle Conrot. “We know that one size does not fit all and we are working on how to set up more segmented channels allowing us to be efficient while meeting all our patients’ needs.”

For the head of global logistics and supply chain operations, the individual approach to patients also extends to her team of employees. The mix of people reflects the diversity of the business and she takes pride in stimulating an all-inclusive environment. “Diversity is one thing but inclusion is even more important,” says Conrot.

How has your career path developed?

“I’ve spent my entire career – 27 years – at Roche. I studied pharmacy in Strasbourg and had the opportunity to do an internship at Roche. I then got the opportunity to do my PhD in the sterile manufacturing environment. Since then I’ve never left Roche as the right doors opened at the right moment. About 23 years ago when I joined the long-range planning team, that was not (at least at that moment) a logical step for a pharmacist to move into supply chain. During my time leading the contract manufacturing organization my pharmaceutical background and my technical knowledge helped me, for example, to challenge some promises of our CDMOs.

I also had the great opportunity to manage the supply chain for our German affiliate and to closely experience the needs of our customers and patients and, with my team, make sure that the products were received on time.

I never really actively searched for a new job but I think my network helped. I was always curious and took the risk to explore opportunities that were not the standard. Today when I have development discussions with my team I emphasise that your career is in your own hands. Sometimes a door might open when you think it’s the right moment, but when is the right moment? You must own your own development and it’s important to pack your backpack with a broad variety of experiences. Roche has given me the opportunity so far to have a very diverse career.”

What are you responsible for today?

“I’ve led global logistics and supply chain operations for the Pharma division for the last 4 ½ years. With my team of nearly 100 people we set the strategy for the logistics framework in Roche Pharma; we configure how to ship product, including the mode of transportation, and ensure export compliance and logistics. A very important part of the job is to run the daily operations and to ensure a seamless order and distribution management throughout our internal and external manufacturing network to our world-wide customers, providing uninterrupted supply to patients.

We are running several initiatives that lead to cost-to-serve and efficiency gains, using digital technology like process mining, automation and robotics.

Our North Star is the Roche Ambition and we add value by focusing on efficient and sustainable supply chain and logistics operations, robust processes and by driving continuous improvement activities in our E2E network and transportation framework.”

What did the first wave of the Covid pandemic mean for Roche?

“We had always talked about a VUCA world. March 2020 was really that moment. It was unexpected, so it was bumpy and hectic, yet it was the moment to excel and show that we can make it happen: Logistics and operations had to ensure the supply of medicines to destinations wherever they were needed. And we made it.

One of our products Actemra can be used to treat severe cases of Covid. Production at a new site was ramped up and we had to set up supply chain processes accordingly. At the same moment, the whole freight network was disrupted: planes were grounded and borders closed.

My logistics team together with our logistics service provider proactively worked out a business continuity plan to assess our needs with the current market situation. There are lots of examples of great creativity and thinking out of the box: For example, we couldn’t get our products into Costa Rica and India because there were no flights. The collaboration between Roche, the Swiss authorities and SWISS airline led to us using the repatriation planes (flying empty out of Switzerland) to collect stranded passengers) to bring our products to Costa Rica and India.

We have always been good at firefighting. Now we are looking at how can we sustain the ability to accelerate activities and establish this is a new norm. We continue to use the business continuity plan, especially for unforeseen events such as the disruption at Shanghai airport recently.”

How did you arrange the business continuity meetings so that the teams were flexible and responsive? Does the continuity plan still help you, especially during this period of raw material and transport capacity shortages?

“From a leadership point of view it was an interesting experience. I tried to give the team space to run the operations and avoided stepping in, even though there was a lot of nervousness. I agreed with the team leader when I should give support and when anything should be escalated.

I supported the logistics team with the structure for the business continuity plan and the managing of the internal and external stakeholders.

We are still using our continuity planand perform the regular lane assessment. We check the monthly market analytics for developments in airfreight capacity and we are looking at sea freight, from a resilience, sustainability and risk mitigation point of view. This gives us more options. Procurement keeps a close eye on ingredients that are at risk. So far, we’ve managed the constraints in a sustainable way by being proactive. We also share our plan with our other divisions in Diagnostics and Diabetes Care, and try to collaborate as much as possible, such as organizing common charters flights.”

Has the profile required in Logistics and Operations changed since the start of the pandemic, bearing in mind that the pharmaceutical sector is very structured and suddenly everyone has to be more agile?

“We did not wait for the pandemic to start our transformation journey. When I took over the organization 4 ½ years ago, I inherited teams from logistics and supply chain with very different mindsets. We realized that we needed to work in one direction with a common vision. Our purpose at that time was “Driving operations now while transforming for the future”. We were on our journey to become more lean and agile, by continuous improvement, introducing standardization and creating end-to-end roles. Our focus was added-value activities, eliminating waste and challenging what we had been doing previously. So far we have reached 25% efficiency gains, a reduction in headcount and an increase in our employee engagement.

The team has been great in meeting the challenges. To stay closely connected to all levels of the organisation and to sense the pulse, I regularly do what I call ‘skip the level’ or “Gemba walks”. I skip the team leader and talk directly to the team about its challenges, the ideas for continuous improvement, and how they are adding value. These discussions today are completely different to two years ago.

For me, my people are the most important asset in operations and transformation. We need to ensure that they are part of the journey. A decade or two ago you were given a SOP and you just executed. Now we want to empower people and give them accountability. That does require a change of mindset – for leaders and for our people. For some leaders it is difficult to let go and for other people it is difficult to take the responsibility. It is an ongoing learning journey for both me and my team; we have been at the forefront of exploring new ways of working and creating the space for self-managed teams. Sometimes it feels like flying a plane while still building it.”

We talk about giving people empowerment but you do need to set boundaries and give guidelines. How do you train people to explore the space yet stay within the limits?

“I really like the VACC-leader model. A leader should be a Visionary, Architect, Catalyst and Coach.

The leadership framework should embed all of these aspects, depending on the situation. It really helps me to co-create the boundaries with my teams – sometimes broad, sometimes narrower. But these should be clear and easy to understand for everybody.

I see my role as a leader is to co-create a vision with a clear purpose. In this way I contribute to the broader Roche Ambition, help the teams to resolve and remove the hurdles, give guidance to accelerate and coach and develop my people.”

A few years ago you started to focus on different supply chain channels rather than one size fits all. What are the consequences of this segmented way of working, in particular for patients?

“On one hand we are pushing processes to be more lean, efficient and standardised but indeed, we realize that one size no longer fits all. Therefore, we need to set up segmented supply chains taking into consideration the product specificity, the channels, the markets and the patient needs. We operate a handful of supply chains, ranging from direct supply to patients for very specific products, to the more traditional supply chain – from regional hub to affiliate distribution center, wholesaler, pharmacy etc. We continue to work on getting this balance between the standardization that’s needed to ensure efficiency and the ability to fully fulfil specific patient needs with additional integrated services.”

So pharma is also getting into omni channeling. Do you map out channels to ensure the supply chain is especially designed for this purpose?

“We are currently aiming to get a better understanding of what the market and the patients need, rather than assuming that as a supply chain we know everything. We hear that some patients would see a benefit in medicines being delivered to their home while others do not want the illness (and the medicines) entering their home and want to go to the hospital to receive care.

Even between countries, one product in the portfolio can require a very different supply chain, depending on the healthcare and regulatory systems.”

Is your 4PL also helping you to achieve segmentation in the supply chain?

“As our portfolio is changing the one size fits all solution is not flexible enough to meet our future needs. We are working on establishing segmented channels for the respective products. Additionally, we collaborate with our 4PL on cost-to-serve and continuous improvement initiatives, for example, making better usage of full truck loading. We realized that when we distribute into Europe from Switzerland, trucks are sometimes leaving 3, 4 or 5 times a week for one destination. We believe we can consolidate to be more efficient and also have a positive impact on the environment.”

Global supply chains, in all industries, seem to be in turmoil due to shortages of materials, transport capacity, labour, etc. What are your current challenges?

“The most important and non-negotiable part is keeping the business running and ensuring that products move through the supply chain to reach our patients. We do this by keeping the business continuity plan up-to-date and looking ahead to assess the whole market situation in collaboration with the 4PL.

The second challenge is that the portfolio is changing. We are moving towards a more differentiated portfolio of products. The challenge here is to set up most efficient segmented supply chain for those products.

The third challenge is around patient/customer centricity and the need to fully understand patients’ needs so that we deliver the medicine to where it’s required in the most efficient and fastest way.

Fourthly, we need to embrace the digital technologies available to simplify our work and eliminate waste and the activities that add no value. Over the last two years we have consistently used process mapping to analyse how lean, or not, we are. Based on that we have identified certain parts of the processes that can be automated to make efficiency gains. The next step is to use the robotic process applications to automate some processes.

The mindset and acceptance toward digital technology has changed a lot in the last years. 2 ½ years ago people were worried that they would lose their jobs and be replaced by robots. Now the teams are very proud to participate and identify non-value adding activities.

That’s why the job is so exiting; there’s so much to learn and to do in order to accelerate our activities further and make an impact.”

A lot of hospitals can improve their supply chain and decrease waste. By being more patient centric do you have the opportunity to extend the supply chain downstream and improve the supply chain in hospitals?

“Our vision within the Pharma division to bring 3-5 times more medical advances for patients at 50% less cost to society. Reducing end-to-end cost, including the costs and efforts in hospitals and the healthcare systems, is one way we can contribute to reducing cost to society. By being patient centric and reaching patients in a more efficient way, including all the sustainability aspects, will help us achieve this.”

How easy is it to get new talent and the right influx of cultural diversity into the organization?

“We try to give our people room to develop and to broaden their knowledge. We also support our teams to develop new skills, especially skills we will need in future, such as digitalization, automation, understanding data and then taking action.

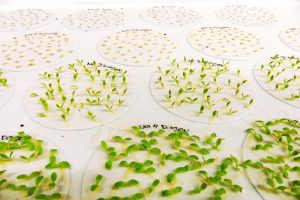

We also offer internal rotation programs and we have students who join us to do specific projects for their thesis. Collaboration with universities, such as MIT-Zaragoza, brings in fresh ideas.

At Roche there is a big focus on diversity and inclusion. I ensure diversity in my team set-up. I look at people’s backgrounds, nationalities and their experiences, not from a pure diversity point of view, but also to ensure that we include different mindsets, views and behaviours in the team. The most important element is inclusion and I strive to create an environment where every employee feels safe and valued and is able to bring the best version of themselves to work every single day.”

If you look five years ahead, what do you think you would have liked to have achieved and do you have any personal ambitions?

“I would like to be recognized as a trusted and inclusive leader that brings value to the people in the organisation and to the company, a leader that makes an impact, drives continuous improvement and delivers results for the company. I would like to be seen as a role model, supporting the development of my people and my organisation, making them feel valued and empowered.

I truly enjoy making a difference and want to continue to make an impact, for my team, for my company and for our patients or customers. It is important for me to stay true to myself, independent of situations, and stay curious to learn and to grow.

I aim to balance my career with my personal life, and spend quality time with my family and partner. Four years ago I bought a villa in Sri Lanka, a country that I’ve fallen in love with. Within the next few years I would like to learn Sinhala (Sri Lankan language) and related to that I would like to learn more about the Ayurveda culture and its natural remedies.”